Diagnostic Equipment

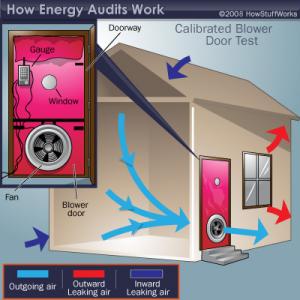

A blower door is a powerful, variable-speed fan that can be temporarily mounted into an exterior door frame to provide controlled air flow for analysis. The way that air flows through a building can have a serious impact on air quality, comfort and energy expenses. The use of a blower door allows air flow through a structure, and the resulting loss of heat can be immediately quantified, providing a way to pinpoint the location of air leaks.

How it Works

When air pressure and air flow are controlled and measured, they can provide data about how airtight a building is. The three variables involved are pressure, flow and holes or leaks. A change in one of these factors will produce a change in atleast one other factor. Since the goal of a blower door test is to locate air leaks in the building envelope, data regarding air pressure and flow can provide information about the holes, which may otherwise be tough to find.

The blower door utilizes controlled differences in air pressure to collect data. Once installed in an exterior door frame, the air pressure inside a building can be changed in relation to the outside pressure by forcing air into or out of the interior. The difference in pressure forces air through holes or leaks in the building envelope. The pressure and air flow are measured by gauges, which are part of the blower door equipment. By measuring the pressure and air flow in relation to each other, the airtightness of the building envelope can be quantified. The amount of air flow needed to create a change in pressure increases as the airtightness of the building envelope decreases. A well-sealed building requires less air flow to generate a change in pressure.

Finding the Problems

During a blower door test, the interior air pressure needed to be maintained in order to gather useful data is 50 pascals, which is roughly equal to the pressure created when a 20-mph wind hits the building. The blower door equipment has a gauge to indicate when this pressure has been achieved, as well as a gauge to indicate the cubic feet per minute (CFM), which is the standard unit of measure for air flow. Air flow in a well-sealed building will generally be less than 1,500 CFM at 50 pascals. Air flow above 4,000 CFM would be considered leaky. This is valuable data that can be acquired in about half an hour with the use of a blower door.

When looking for air leaks, check through basement rim joists, holes for plumbing traps under tubs and showers, cracks between finish flooring and baseboards, utility chases, plumbing vent-pipe penetrations, kitchen soffits, fireplace surrounds, recessed can lights, and cracks between partition top plates and drywall. These are all common places where significant leaks can develop.